Structures Lead

STRUCTURES

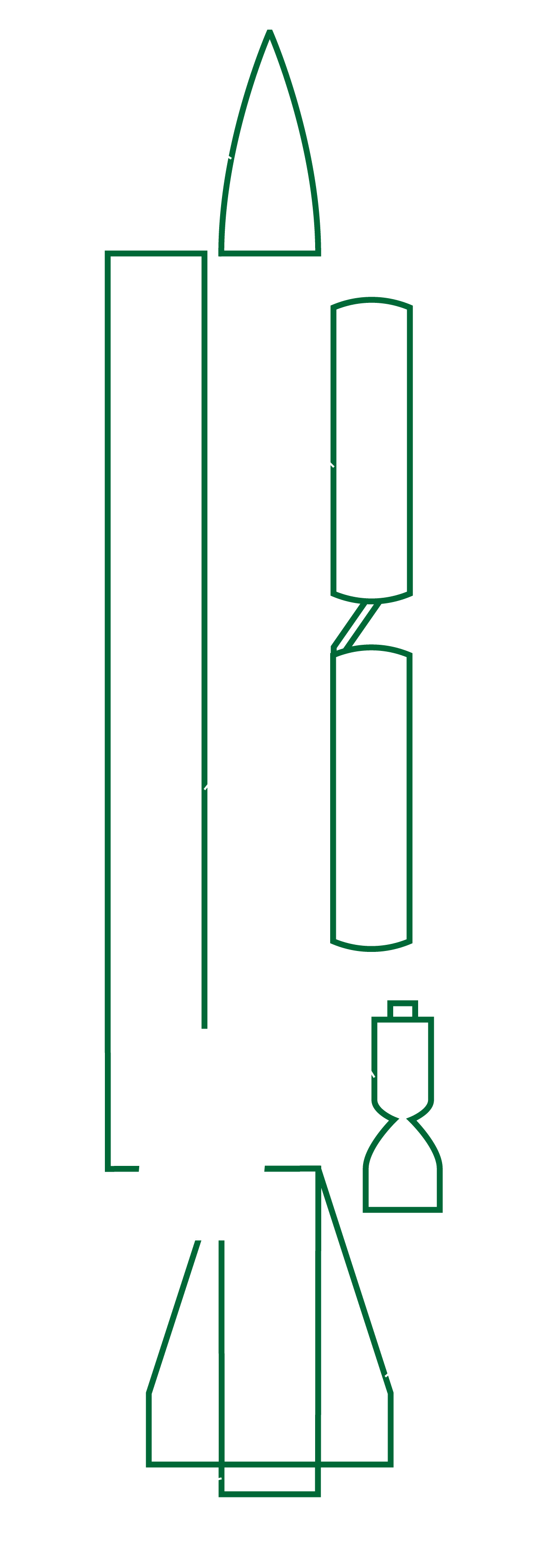

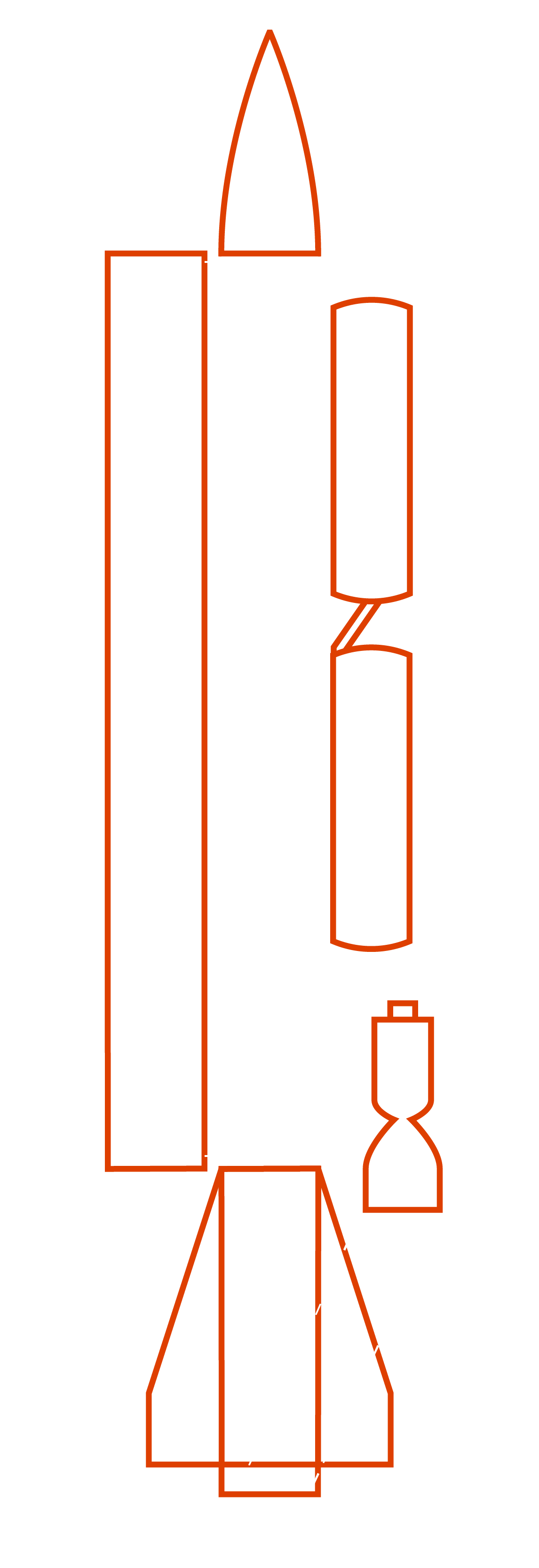

The Structures team makes everything that you can see on the rocket, including the airframes, nose cone, fins, and couplers that link everything together. Structures designs these systems for integration and runs structural analysis on all of the parts to ensure their integrity. Structures manufactures most components out of composites, such as carbon fiber, to reduce weight while retaining strength. Aluminum is machined to create high-strength couplers that hold the rocket together and provide mounting points for recovery and avionics equipment. Additionally, Structures runs flight simulations and calculates the optimal geometry and location of our fins to maximize stability, while minimizing drag and weight. Structures also includes the recovery system, which includes two parachutes, two pyrotechnic devices that deploy the parachutes, and the electronics that signal the pyrotechnics. If you want to learn about analysis or manufacturing with composites and metal materials, structures might be the team for you!